Lean Process Improvement: Tools and Techniques

In today’s fast-paced business world, efficiency and continuous improvement are key to staying competitive. Enter Lean Process Improvement, a methodology that helps organizations streamline operations, reduce waste, and enhance productivity. Whether you’re a seasoned professional or just starting your lean journey, this guide will walk you through essential tools and techniques to optimize your processes. Let’s dive in! 🚀

Table of Contents

1. What is Lean Process Improvement?

2. Key Lean Tools and Techniques

3. How to Implement Lean in Your Organization

4. Benefits of Lean Process Improvement

5. Conclusion

6. FAQs

What is Lean Process Improvement?

Lean Process Improvement is all about maximizing value by minimizing waste. Originating from the Toyota Production System, this approach focuses on creating more value for customers with fewer resources. It’s not just a set of tools, but a mindset of continuous improvement.

Key Lean Tools and Techniques 🛠️

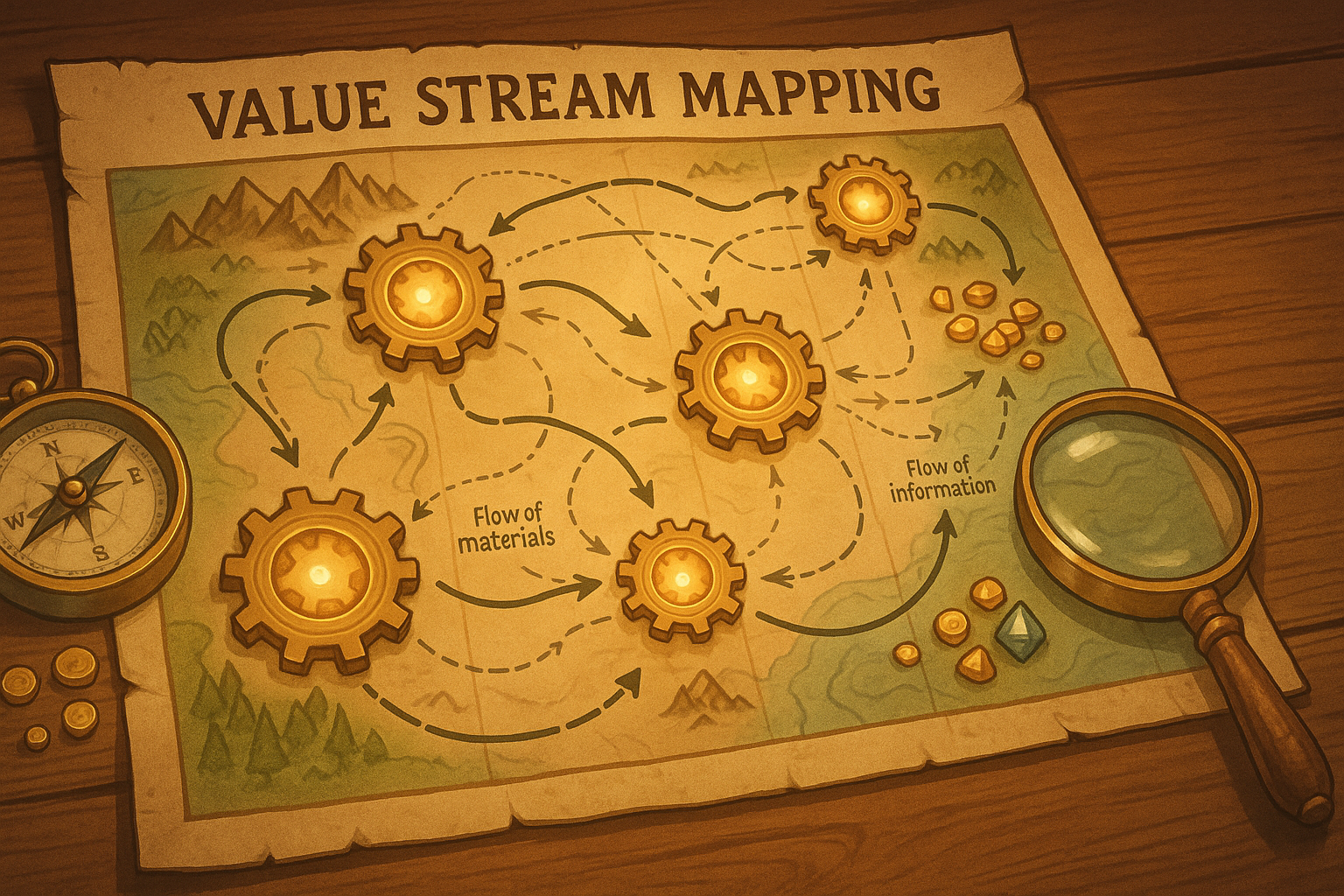

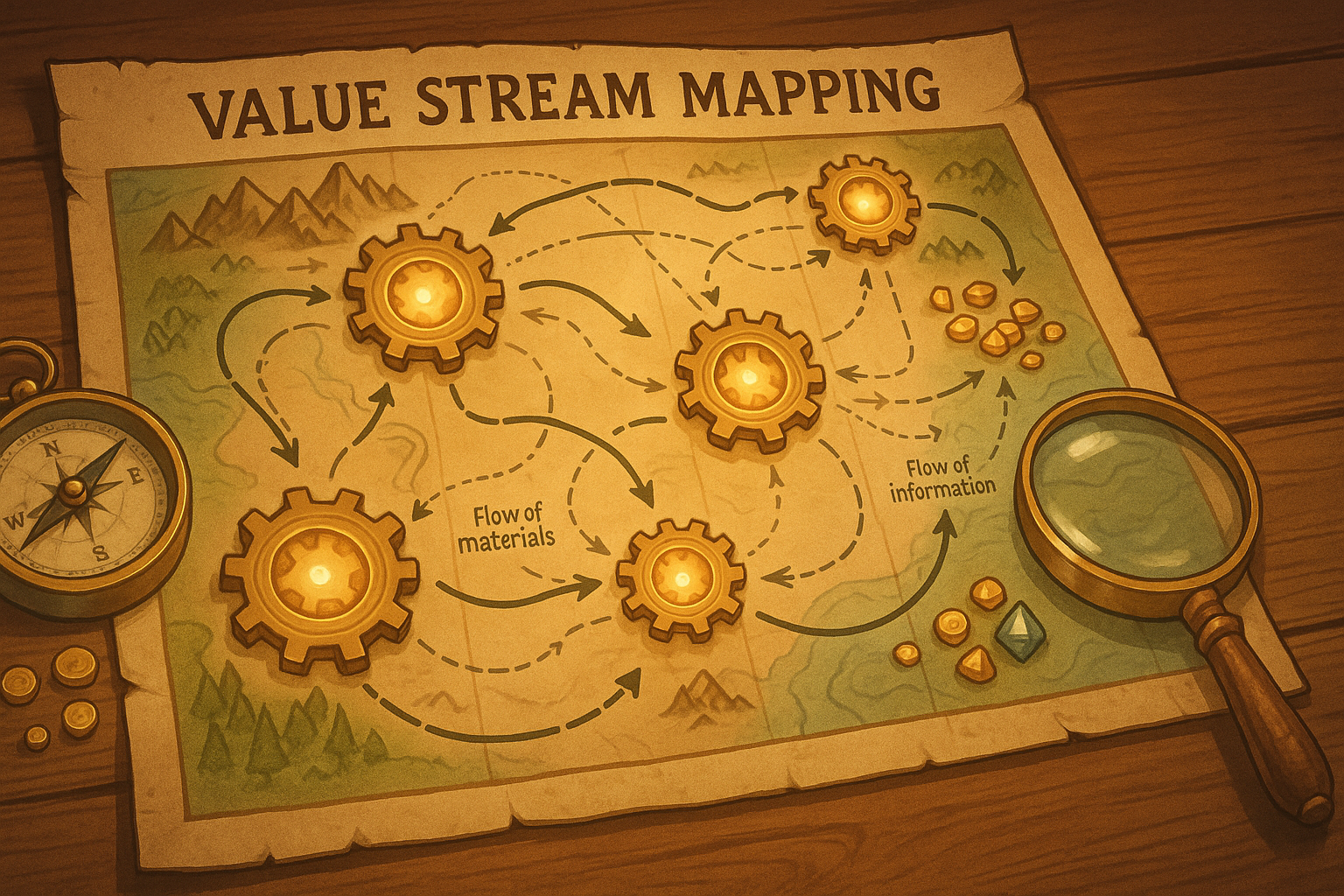

1. Value Stream Mapping

This visual tool helps you map out the current flow of materials and information in a process. By identifying each step, you can spot inefficiencies and areas for improvement. It’s like a treasure map for finding hidden potential! 🗺️

2. 5S System

Sort, Set in order, Shine, Standardize, and Sustain. This technique focuses on organizing the workplace to improve efficiency and safety. Imagine a workspace where everything is in its place and ready for action—dreamy, right? 🌟

3. Kaizen

Kaizen means “continuous improvement” in Japanese. It encourages small, incremental changes that lead to significant improvements over time. Think of it as taking tiny steps to climb a mountain. 🏔️

4. Kanban

This scheduling system helps manage workflow effectively by signaling when to produce more or stop production. It’s like having a traffic light for your processes, ensuring nothing gets too congested. 🚦

How to Implement Lean in Your Organization

Implementing Lean is not a one-size-fits-all approach. Start with a clear understanding of your current processes and identify areas ripe for improvement. Engage your team—after all, they’re the experts in their workflow. Training and empowering employees to think lean can lead to a culture of continuous improvement.

Benefits of Lean Process Improvement 🌟

The advantages of adopting lean methodologies are plentiful. From reduced operational costs and improved efficiency to enhanced customer satisfaction and employee morale—lean is a win-win for everyone involved.

Conclusion

Lean Process Improvement is more than just eliminating waste; it’s about creating a culture of ongoing progress and innovation. By utilizing the right tools and techniques, your organization can unlock new levels of efficiency and success. Ready to embark on your lean journey? The time is now! 🚀

FAQs

What industries can benefit from Lean Process Improvement?

Lean principles can be applied across various industries, including manufacturing, healthcare, finance, and more. Any organization looking to optimize processes and reduce waste can benefit from lean methodologies.

How long does it take to see results from Lean Implementation?

Results can vary, but many organizations start seeing improvements within a few months. The key is maintaining momentum and continuously seeking areas for improvement.

Is Lean Process Improvement expensive to implement?

While there may be initial costs for training and tools, the long-term savings and efficiency gains typically outweigh these expenses, making lean a cost-effective strategy.

What are common challenges in implementing Lean?

Common challenges include resistance to change, lack of training, and inconsistent application of lean principles. Addressing these challenges with clear communication and leadership support is essential.

Lean Process Improvement is a journey, not a destination. By embracing its tools and techniques, you can lead your organization towards greater efficiency and success. Ready to start your lean transformation? Let’s get going! 💪